Cable gland connector waterproof and fireproof measures

Cable Gland Connector Specification Requirements

(1) Basic requirements for wire lugs

1. The resistance of the joint cannot be greater than that of the wire;

2. The mechanical strength of the joint cannot be less than the strength of each wire itself;

3. The insulation of the joint should not be less than that of the mainline;

4. The corrosion resistance and oxidation resistance of the terminal head are good.

5. Good electrical conductivity, the same as the cable body, can transmit the current specified by the allowable carrying capacity for a long time and stably without causing local heating;

6. Sufficient insulation strength is required to withstand long-term high voltage and short-term overvoltage under working conditions;

7. Warm reminder from the cable gland connector manufacturer, an excellent protective structure requires weather resistance and corrosion resistance, as well as good sealing and sufficient mechanical strength.

(2) Basic specifications for wire lugs

1. Reserve a length of about 15-20cm for the wire head of the wire box, and then scrape off the remaining part of the insulation, and scrape off the paint layer and oxide layer.

2. Wiring color standard: Generally, red is used for live wires, blue is used for neutral wires, and the pattern is used for ground wires; if it is a dual-control switch with multiple live wires, other colors are required to distinguish them.

3. Hot tin. All the thread ends should be tinned according to the specification.

Picture of the Cable Gland Connector

How to Connect the Cable Gland

Before connecting the cable, cut the insulating ends on both sides into a conical shape (reaction force cone), and leave the inner shield of the wire about 10mm longer than the conventional one. After crimping or welding, remove the burrs and flashes on the surface of the connecting pipe, and use Wipe off the metal powder on the surface of the connecting pipe with a white cloth moistened with gasoline. At this time, it is necessary to fill up the pressure pit of the connecting pipe with a semi-conductive rubber self-adhesive tape, and use a semi-folding method to wrap and fill the connecting pipe and the semi-conductive inner core of the wire core. The gap between the shielding layers must be carefully wrapped, and the gap should be evenly pressed by hand to play the role of a uniform electric field.

What are the types of cable connectors?

The cable gland connector manufacturer tells you that the connection methods of cable gland connectors are divided into “cross” connection, “one-word” connection and “T” connection.

The correct way to deal with the joint: 1. When cutting off the end of the thread, you only need to squeeze the end of the thread with wire cutters, then wrap the thread around the jaws, and turn it hard to disconnect it. 2. The joint at the dry place of the power supply needs to be wrapped twice with insulating tape, then wrapped twice with insulating self-adhesive tape, and finally wrapped with plastic tape twice. The three common connection methods of cables are divided into “standard connection method”, crimping wire connection method” and “fireproof tape isolation method”.

The standard connection method means that there is no power connector. If there is a connector for the power supply, it is easy to cause a short circuit, ignition, and poor contact. In particular, pay attention to whether the power connector in the home exists.

The crimping and risking wiring method is to use crimping pliers to crimp the wires, and put the crimping pliers on the crimping and risking. The crimping and risking wiring method is the most standardized and practical method.

The fireproof tape isolation method is often used in higher projects, such as high suspended ceilings. Note that the main line cannot be broken. The function of using fireproof tape is to prevent electrical appliances from being ignited and burned to parts, and the outside is tightly wrapped with insulating tape.

Warm suggestions from cable connector manufacturers: it is dangerous to connect cables, and the irregularities in the connection will have a great impact on the safety of electricity use in the future. It is recommended to find professional personnel to operate.

Waterproof and fireproof measures should be taken at the cable gland connectors

1. Cable technology

Generally speaking, the cable head is the weak link of the cable insulation, so strengthening the monitoring and management of the cable head is an important part of cable fire protection.

(1) The terminal cable head must not be placed in the cable trench, cable tunnel, cable box, or cable interlayer.

(2) The intermediate cable heads placed in cable trenches, cable tunnels, cable trough boxes, and cable interlayers must be registered and monitored with various monitoring equipment.

(3) When the cable head is found to have abnormal temperature rise or smell or smoke, it should be withdrawn from operation as soon as possible to avoid the cable head from catching fire during the operation.

(4) A sufficient safety distance should be ensured between the intermediate cable heads. More than two cable heads should not be placed in the same position, and strict sealing measures should be taken between the cable heads and other cables.

The above is the summary of the cable gland connector manufacturers for you. I hope it can help you with the relevant content and information about the cable gland connectors.

Nylon Cable Gland Divided Structure G Thread The main function of nylon cable joint

The main function of the cable joint is to make the line unobstructed, keep the cable sealed, and ensure the insulation level of the cable joint so that it can run safely and reliably. If the seal is not good, not only oil leakage will cause the oil-impregnated paper to dry up, but also moisture will invade the inside of the cable, reducing the insulation performance of the paper.

The cable joint is also called the cable head. After the cable is laid, to make it a continuous line, each section of the line must be connected as a whole, and these connection points are called cable joints. The main function is to make the line unobstructed. The phenomenon of heating of the wire joints generally first manifests as a peculiar smell around the wire joints, which can be smelled. This is because the heat of the wire joints makes the outer insulation layer smell; secondly, smoke and redness are emitted from the wire joints. , The outsourcing insulation layer turns black, catches fire, or even disconnects.

Nylon Cable Gland Divided Structure G Thread The main function of nylon cable joint

The main function of the cable joint is to make the line unobstructed, keep the cable sealed, and ensure the insulation level of the cable joint so that it can run safely and reliably. If the seal is not good, not only oil leakage will cause the oil-impregnated paper to dry up, but also moisture will invade the inside of the cable, reducing the insulation performance of the paper.

The cable joint is also called the cable head. After the cable is laid, to make it a continuous line, each section of the line must be connected as a whole, and these connection points are called cable joints. The main function is to make the line unobstructed. The phenomenon of heating of the wire joints generally first manifests as a peculiar smell around the wire joints, which can be smelled. This is because the heat of the wire joints makes the outer insulation layer smell; secondly, smoke and redness are emitted from the wire joints. , The outsourcing insulation layer turns black, catches fire, or even disconnects.

What are Nylon Cable Glands?

The cable joint is a component in the cable line, which is used to realize the connection of two cables and improve the electric field at the end of the two cables. When one end of the cable is connected to other electrical equipment, a cable terminal is required; when one end of two cables is connected to a cable line, a cable intermediate joint is required, and the cable terminal and the intermediate joint are collectively referred to as a cable end. The main function of the cable head is to seal the cable. When the cable leaves the factory, both ends are sealed, but when laying or connecting, its ends must be cut open, which destroys its sealing. If the end of the cable is not sealed during laying or the quality of the cable head is unqualified, the cable head will leak oil, and finally, the insulating oil will dry up, and the insulation performance will be greatly reduced, which will affect the safe operation of the cable.

What are Nylon Cable Glands?

The cable joint is a component in the cable line, which is used to realize the connection of two cables and improve the electric field at the end of the two cables. When one end of the cable is connected to other electrical equipment, a cable terminal is required; when one end of two cables is connected to a cable line, a cable intermediate joint is required, and the cable terminal and the intermediate joint are collectively referred to as a cable end. The main function of the cable head is to seal the cable. When the cable leaves the factory, both ends are sealed, but when laying or connecting, its ends must be cut open, which destroys its sealing. If the end of the cable is not sealed during laying or the quality of the cable head is unqualified, the cable head will leak oil, and finally, the insulating oil will dry up, and the insulation performance will be greatly reduced, which will affect the safe operation of the cable.

Classification of cable glands

① According to the joint material, it is divided into plastic cable joints and metal cable joints. Metal cable joints are further divided into porous metal cable waterproof joints, anti-bending metal cable joints, double-lock metal cable waterproof joints, plastic hose cable joints, metal hose cable joints, etc.

②According to the installation site, it can be divided into the indoor type and outdoor type.

③ According to the production and installation materials, it can be divided into heat-shrinkable type (the most commonly used one), dry-pack type, epoxy resin casting type, and cold-shrinkable type.

④ According to the wire core material, it can be divided into copper core power cable head and aluminum core power cable head.

There are two types of cable terminals: indoor and outdoor. Nylon cable joint manufacturers warmly remind us that because outdoor cable terminals are easily affected by wind, rain, ice, snow, and ambient climate, the working conditions are poor and the structure is relatively complicated. The working condition of the indoor cable terminal is better, no waterproof device is required, and the cable core wire can be directly connected to the equipment.

Classification of cable glands

① According to the joint material, it is divided into plastic cable joints and metal cable joints. Metal cable joints are further divided into porous metal cable waterproof joints, anti-bending metal cable joints, double-lock metal cable waterproof joints, plastic hose cable joints, metal hose cable joints, etc.

②According to the installation site, it can be divided into the indoor type and outdoor type.

③ According to the production and installation materials, it can be divided into heat-shrinkable type (the most commonly used one), dry-pack type, epoxy resin casting type, and cold-shrinkable type.

④ According to the wire core material, it can be divided into copper core power cable head and aluminum core power cable head.

There are two types of cable terminals: indoor and outdoor. Nylon cable joint manufacturers warmly remind us that because outdoor cable terminals are easily affected by wind, rain, ice, snow, and ambient climate, the working conditions are poor and the structure is relatively complicated. The working condition of the indoor cable terminal is better, no waterproof device is required, and the cable core wire can be directly connected to the equipment.

Conductor connection requires low resistance and sufficient mechanical strength, and no sharp corners can appear at the connection. Brass cable gland manufacturer reminds you that crimping is commonly used to connect medium and low-voltage cable conductors, and attention should be paid to crimping:

(1) Select a conductor connecting pipe with appropriate conductivity and mechanical strength.

(2) The matching gap between the inner diameter of the crimping tube and the outer diameter of the connected core is 0.8-1.4mm.

(3) The resistance value of the joint after crimping should not be greater than 1.2 times that of the equal-section conductor, and the tensile strength of the copper conductor joint should not be lower than 60N/mm2.

(4) Before crimping, the outer surface of the conductor and the inner surface of the connecting pipe are coated with conductive glue, and the oxide film is destroyed with a wire brush.

(5) Use a file or sandpaper to smooth the sharp corners and burrs on the connecting pipe and core conductor.

Inner semiconductor shielding treatment Where the cable body has an inner shielding layer, the inner shielding layer of the joint of the conductor part of the crimping tube must be restored when making the joint. They can communicate with each other to ensure the continuity of the inner semiconductor so that the field strength at the junction is evenly distributed.

Treatment of the outer semiconductor shield is a semi-conductive material that acts as a uniform electric field on the outside of the cable and connector insulation. Like the inner semiconductor shield, it plays a very important role in the cable and connector. The outer semiconductor port must be neat and uniform, and it also requires a smooth transition with the insulation, and the semiconductor tape is added to the joint to connect with the outer semiconductor shield of the cable body.

Treatment of cable reaction cones During construction, the shape and size of the reaction cones are accurate and the potential distribution on the entire cone surface is equal. When making cross-linked cable reaction cones, special cutting tools are generally used, and micro-flame can also be used. Slightly heat, and cut with a sharp knife, after the basic shape, then use 2mm thick glass to repair and scrape, and finally use sandpaper to polish from coarse to fine until it is smooth.

Metal shielding and grounding treatment The role of metal shielding in cables and connectors is mainly to conduct cable fault short-circuit currents and shield electromagnetic fields from electromagnetic interference to adjacent communication equipment. In operating conditions, metal shielding is at zero potential under good grounding conditions. After the cable fails, it has the ability to conduct short-circuit current in a very short time. The grounding wire should be reliably welded, the metal shield and armored tape on the cable body at both ends should be firmly welded, and the grounding of the terminal head should be reliable.

Sealing and mechanical protection of joints The sealing and mechanical protection of joints are the guarantees to ensure the safe and reliable operation of joints. Manufacturers of brass cable gland suggest that water and moisture should be prevented from penetrating into the joints. In addition, joint protection grooves should be built or cement protection boxes should be installed at the joint position.

Brass cable gland manufacturers share the key points of cable joints in construction. If you want to know more information, you can continue to pay attention to our website.

Conductor connection requires low resistance and sufficient mechanical strength, and no sharp corners can appear at the connection. Brass cable gland manufacturer reminds you that crimping is commonly used to connect medium and low-voltage cable conductors, and attention should be paid to crimping:

(1) Select a conductor connecting pipe with appropriate conductivity and mechanical strength.

(2) The matching gap between the inner diameter of the crimping tube and the outer diameter of the connected core is 0.8-1.4mm.

(3) The resistance value of the joint after crimping should not be greater than 1.2 times that of the equal-section conductor, and the tensile strength of the copper conductor joint should not be lower than 60N/mm2.

(4) Before crimping, the outer surface of the conductor and the inner surface of the connecting pipe are coated with conductive glue, and the oxide film is destroyed with a wire brush.

(5) Use a file or sandpaper to smooth the sharp corners and burrs on the connecting pipe and core conductor.

Inner semiconductor shielding treatment Where the cable body has an inner shielding layer, the inner shielding layer of the joint of the conductor part of the crimping tube must be restored when making the joint. They can communicate with each other to ensure the continuity of the inner semiconductor so that the field strength at the junction is evenly distributed.

Treatment of the outer semiconductor shield is a semi-conductive material that acts as a uniform electric field on the outside of the cable and connector insulation. Like the inner semiconductor shield, it plays a very important role in the cable and connector. The outer semiconductor port must be neat and uniform, and it also requires a smooth transition with the insulation, and the semiconductor tape is added to the joint to connect with the outer semiconductor shield of the cable body.

Treatment of cable reaction cones During construction, the shape and size of the reaction cones are accurate and the potential distribution on the entire cone surface is equal. When making cross-linked cable reaction cones, special cutting tools are generally used, and micro-flame can also be used. Slightly heat, and cut with a sharp knife, after the basic shape, then use 2mm thick glass to repair and scrape, and finally use sandpaper to polish from coarse to fine until it is smooth.

Metal shielding and grounding treatment The role of metal shielding in cables and connectors is mainly to conduct cable fault short-circuit currents and shield electromagnetic fields from electromagnetic interference to adjacent communication equipment. In operating conditions, metal shielding is at zero potential under good grounding conditions. After the cable fails, it has the ability to conduct short-circuit current in a very short time. The grounding wire should be reliably welded, the metal shield and armored tape on the cable body at both ends should be firmly welded, and the grounding of the terminal head should be reliable.

Sealing and mechanical protection of joints The sealing and mechanical protection of joints are the guarantees to ensure the safe and reliable operation of joints. Manufacturers of brass cable gland suggest that water and moisture should be prevented from penetrating into the joints. In addition, joint protection grooves should be built or cement protection boxes should be installed at the joint position.

Brass cable gland manufacturers share the key points of cable joints in construction. If you want to know more information, you can continue to pay attention to our website.

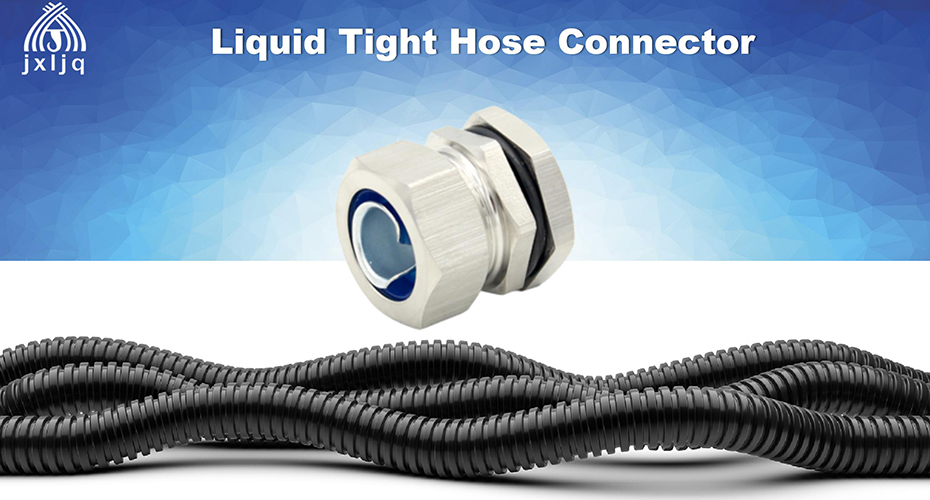

How to choose the right size of Liquid Tight Hose Connector?

First measure the inner diameter of the hose, select the appropriate conduit fitting according to this data( mean,the outer diameter of the ferrule, will suitable for the inner diameter of the hose)

For example, the size JX-M10*1.5 φ8, means,the the outer diameter of the ferrule of conduit fittings is 8mm, and it will suitable for hose which inner diameter is φ8.

How to install the Liquid Tight Hose Connector?

One side of Liquid Tight Hose Connector has a sleeve that pushes onto the conduit, forming a tight seal that stands up to wet and corrosive environments.

The other side of Liquid Tight Hose Connector inserts into a fixture, electrical box, or enclosure and tightens down with an included lock nut.

JIXIANG CONNECTOR providing high quality Liquid Tight Hose Connector in different material to meet your requirements.

Brass Liquid Tight Hose Connector

Brass Liquid Tight Hose Connector are made of high quality nickel plated brass that can simultaneously complete the two tasks of connecting the cable protection hose to the device and fixing the cable.

Zinc Alloy Liquid Tight Hose Connector

Zinc alloy Liquid Tight Hose Connector with good waterproof performance, safety and reliable quality. High quality zinc alloy material can resist salt, acid, alkali, ethyl alcohol and general solvent.

Stainless Steel Liquid Tight Hose Connector

Durable stainless steel Liquid Tight Hose Connector are available in material stainless steel SS304 or SS316, witch offers low conductivity and high corrosion resistance. High compression strength and withstands operation over a wide temperature range.

JIXIANG CONNECTOR is a professional manufactures from China, with completely independently producing and supporting OEM/ODM orders.

Any inquires or questions of Liquid Tight Hose Connector, please feel free to contact us.

How to choose the right size of Liquid Tight Hose Connector?

First measure the inner diameter of the hose, select the appropriate conduit fitting according to this data( mean,the outer diameter of the ferrule, will suitable for the inner diameter of the hose)

For example, the size JX-M10*1.5 φ8, means,the the outer diameter of the ferrule of conduit fittings is 8mm, and it will suitable for hose which inner diameter is φ8.

How to install the Liquid Tight Hose Connector?

One side of Liquid Tight Hose Connector has a sleeve that pushes onto the conduit, forming a tight seal that stands up to wet and corrosive environments.

The other side of Liquid Tight Hose Connector inserts into a fixture, electrical box, or enclosure and tightens down with an included lock nut.

JIXIANG CONNECTOR providing high quality Liquid Tight Hose Connector in different material to meet your requirements.

Brass Liquid Tight Hose Connector

Brass Liquid Tight Hose Connector are made of high quality nickel plated brass that can simultaneously complete the two tasks of connecting the cable protection hose to the device and fixing the cable.

Zinc Alloy Liquid Tight Hose Connector

Zinc alloy Liquid Tight Hose Connector with good waterproof performance, safety and reliable quality. High quality zinc alloy material can resist salt, acid, alkali, ethyl alcohol and general solvent.

Stainless Steel Liquid Tight Hose Connector

Durable stainless steel Liquid Tight Hose Connector are available in material stainless steel SS304 or SS316, witch offers low conductivity and high corrosion resistance. High compression strength and withstands operation over a wide temperature range.

JIXIANG CONNECTOR is a professional manufactures from China, with completely independently producing and supporting OEM/ODM orders.

Any inquires or questions of Liquid Tight Hose Connector, please feel free to contact us.